Smart Inpatient Dispensing Solution:Robot-Like System for Picking and Transporting Medicines to Ensure Medication Safety and Create A Healthy Workplace

Department of Pharmacy, Kaohsiung Chang-Gung Memorial Hospital

Overview:

Adverse drug events ranked first in number of patient safety reports in Taiwan, and most were as a result of human error during peak hours of the pharmacy. Fatigued medical personnel are at least 2 times more likely to endanger patient safety. Pharmacists might lose concentration after highly intensive and repetitive dispensing operations for long periods of time and make a mistake that may even cause physical harm.

The volume of injectable drugs varies greatly, and there is a height difference between the material shelves, which requires vertical squatting or high lifting operations. It is difficult for the material racks to be concentrated near the pharmacist's working area, and medicines are often collected from different places. The workspaces are distributed on different floors, which causes the problem of getting medicine across floors.

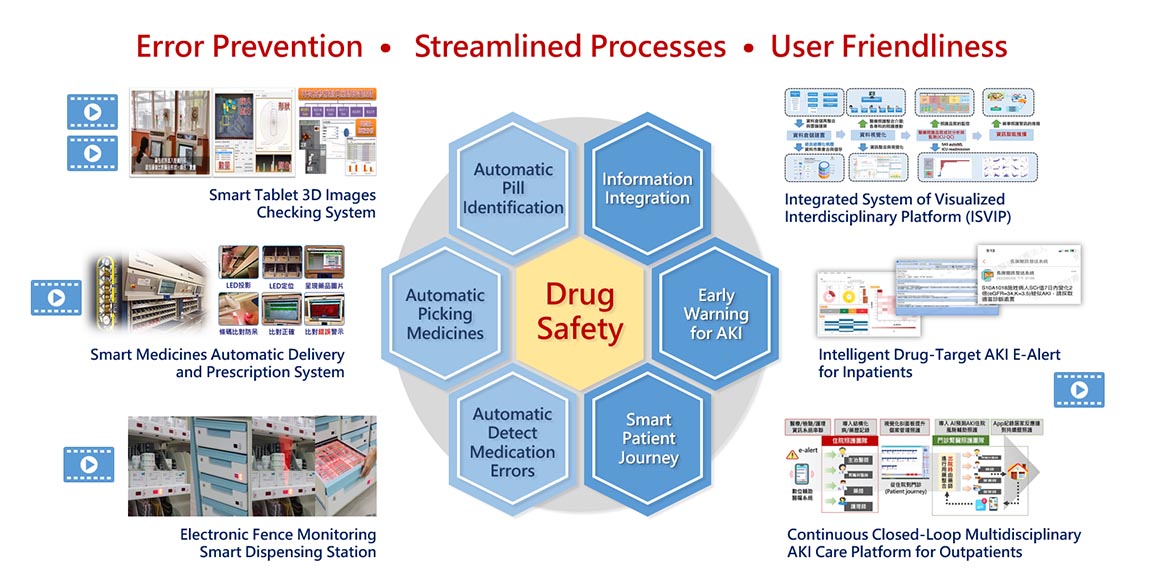

The pharmacy team has formed a cross industry alliance with industrial automation equipment and system integration experts to develop a robot-like system for picking and transporting medicines, to ensure medication safety and create a healthy workplace.

Specific Practices:

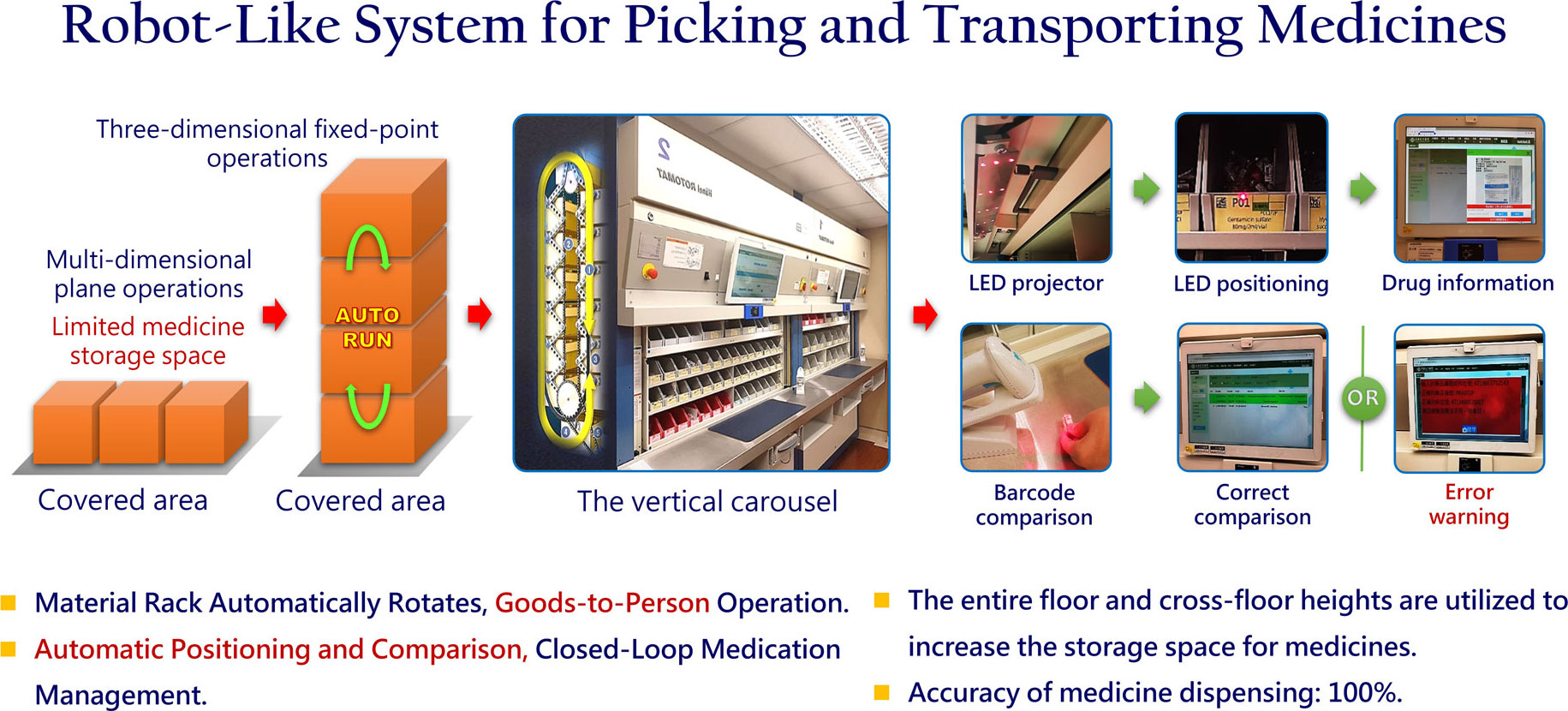

- Material Rack Automatically Rotates, Goods-to-Person Operation:

Applying the principle of industrial vertical rotating material rack, the entire floor and cross-floor heights are utilized to increase the storage space for medicines. When dispensing, the medicine bag barcode is read, and the corresponding material rack automatically rotates to the pharmacist's work surface, reducing the pharmacist's movement, squatting or lifting to get medicine. - Automatic Positioning and Comparison, Closed-Loop Medication Management:

The LED projector module guides the correct storage position. When getting the medicine, read the outer packaging barcode, and the system compares the medicine packaging barcode to be correct. Through the integration of barcode recognition and LED projection positioning, closed-loop management of the dispensing process works. Combined with the concept of the Internet of things, Warehouse Management System (WMS) intelligently connects multiple devices to provide real-time inventory management and remote quality monitoring.

Specific Results:

- Human Factors Improvement:

The user-oriented humanistic concept adjusts the transformation from multi-dimensional plane operations to three-dimensional fixed-point operations.

● Decrease in total distance of operations: 345 km/month.

● Decrease in climbing up and crouching down to get medicine: 60 times/hour/person.

● Significant improvement in neck, shoulder, and wrist sprain of pharmacists (P < 0.05). - Efficiency Improvement:

Cloud computing reorganizes big data of prescriptions, and centralized picking of the same medication improves the overall dispensing efficiency by 68%. - Medication Safety:

Risk management and control are digitalized.

● Interception of incorrect medicine dispensing: 100%.

● Accuracy of medicine dispensing: 100%.

● Replaces 100% of inspections by pharmacist. - Floor Efficiency Management:

Increase in medicine storage per unit area by 209%.

The pharmacy team combined automated equipment and pharmacy management system to develop a robot-like picking and handling system, successfully transforming the once labor-intensive medicine dispensing work, improving the efficiency of medicine selection and medication safety, achieving the goal of closed-loop medication management.

INITIAL INVENTION:

- Light projection positioning rotary medicine delivery machine (Invention Publication Number 202237483).

HONORS:

- 2020 National Healthcare Quality Award Smart Medicine Silver Award.

- 2020 Chang Gung Hospital National Healthcare Quality Award (Excellent Quality).

- 2023 Harvard Business Review: Digital Transformation Award (First Prize).

NATIONAL PROMOTION:

- Observation meeting for workplace health management effectiveness, Department of Labor, 2019.

- Special interview reports, Joint Commission of Taiwan, 2021.