Rapid Transit System for Blood Testing: The Intelligent Skywalk

After outpatients finish the automatic check-in process, tube preparation and blood collection will be proceed at the first-floor phlebotomy counter. The samples are then automatically sent to the central laboratory on the third floor and managed through one-code inspection. The Intelligent Skywalk system features a high-efficiency specimen sorter connected to four automatic track systems through a conveyor track. A robotic arm facilitates rapid specimen handling, organizing, and immediate processing of tests, achieving a maximum throughput of 1200 samples per hour. In 2022, the delivery time for urgent specimens was significantly reduced from 12.9 minutes to 7 minutes (shortened by 45.8%), and the processing time for regular specimens decreased from 16 minutes to 7.8 minutes (shortened by 51.3%). Consequently, the efficiency of specimen transportation improved by an average of 48.6%. The completion rate for reporting emergency samples within 30 minutes averaged 91.6%, and the turnaround time for regular samples was enhanced from 24 hours to 5.5 hours, achieving a 90% success rate. The four automatic track systems work in tandem with the Sysmex hematology analyzer, the specimen pre-processing system, the biochemical analyzer, and the immunological analyzer to conduct tests. The core of information control system in Skywalk is the self-developed "Business Intelligence Calculation Logic". This system intelligently tracks patients’ blood specimens, ensuring optimal distribution and expedited delivery for biochemical and immunological testing. By monitoring each stage on the tracks—including the centrifuge, cup/tube loader, biochemical, and immunological analyzers—the system calculates the most efficient routes for newly collected specimens. It prioritizes urgent specimens, thereby enhancing the overall efficiency of the automatic track system.

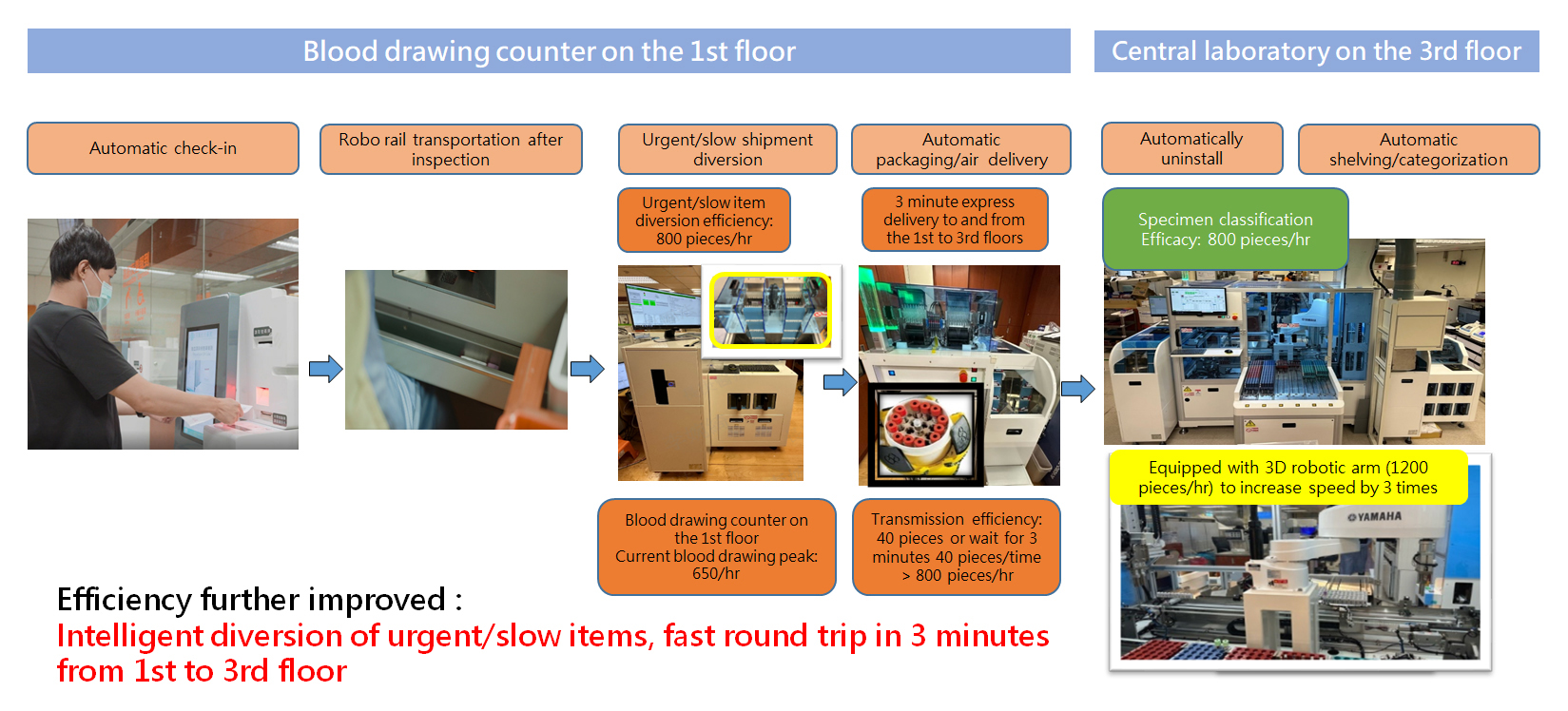

Intelligent transportation of emergency specimens

After blood collection, staff place the specimens onto an under-table track system that automatically conveys them to a collection point. The automatic classification system reads the barcode, records the specimen’s arrival time, and tracks its movement, ensuring specimen transportation safety. It also preliminarily sorts specimens into urgent or regular categories. During peak periods, urgent specimens are prioritized in the delivery system. Regular specimens are processed when no urgent ones are pending. The system swiftly handles up to 40 specimens, then dispatches them to the third-floor central laboratory. This rapid transit takes only 3 minutes and requires no manual handling, with a capacity of 800 specimens per hour. During off-peak hours, the delivery system shifts to a scheduled mode to reduce delivery frequency and conserve energy.

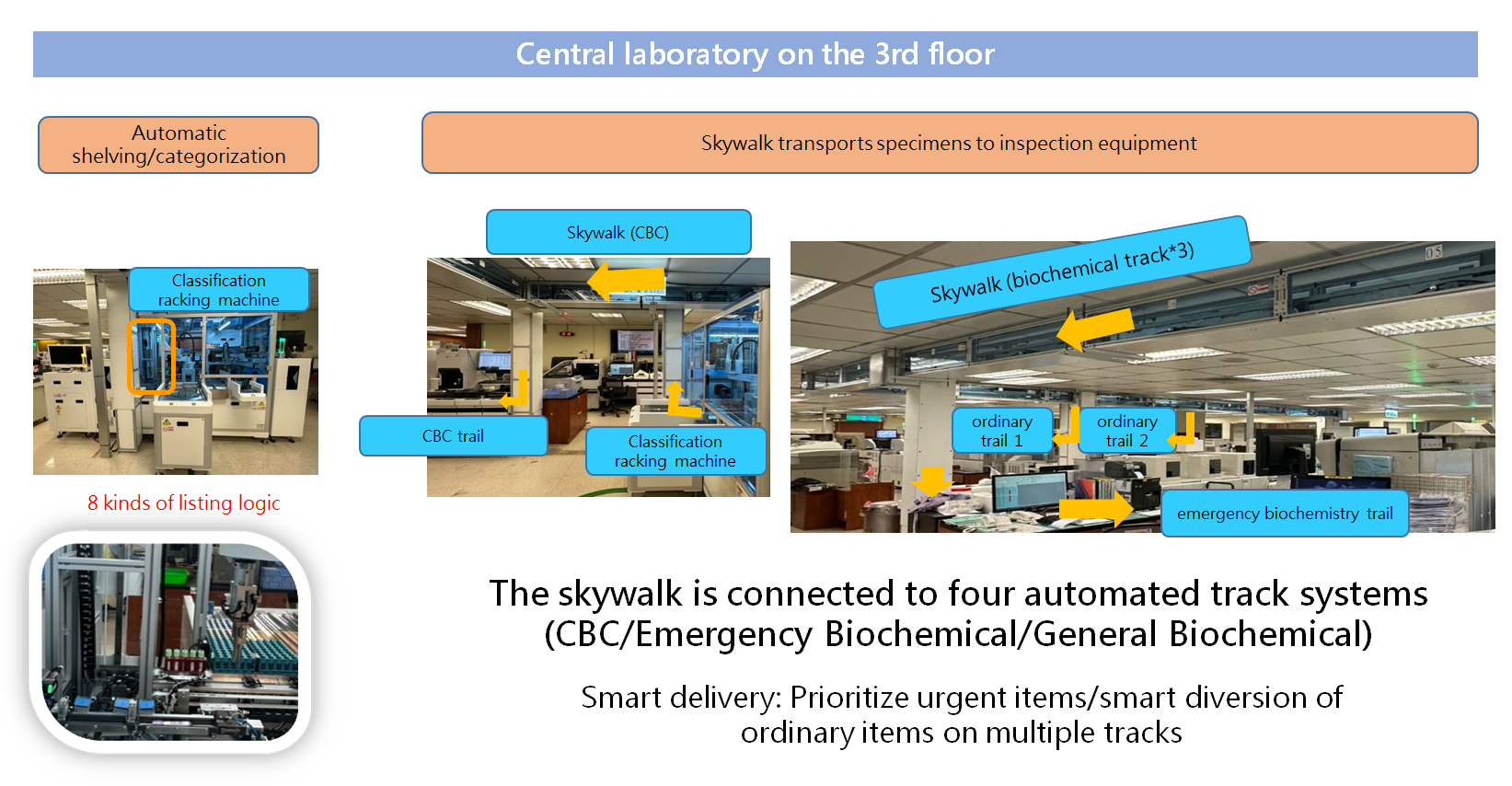

Intelligent Skywalk in Laboratory Medicine Laboratory

After being transported from the first to the third floor, specimens are automatically unloaded by the delivery system into the sorting machine. The system records arrival times and sorts samples by reading barcodes. Specimens suitable for the automated track are shelved immediately, while others are sorted into six drawers according to lab procedures. Over 60% of daily specimens—biochemistry, immunology, blood routine—are processed on the system, a task previously done manually.

Our tailor-made automatic shelving system efficiently sorts samples into three distinct racks—routine blood, emergency biochemistry, and standard biochemistry/immunology—linking four automatic track systems. Utilizing "Business Intelligence Calculation Logic", the system evaluates the progress of nine instruments on the biochemistry/immunology tracks and routes specimens to the quickest available analyzer. Routine blood samples are similarly processed to ensure peak efficiency without manual intervention. Once on the automated track, specimens undergo centrifugation, decapping, aliquoting, and dispensing, rapidly producing biochemical/immunological reports. Our hospital’s LIS automatically verifies tens of thousands of reports daily, with a pass rate exceeding 95%. The testing results that fail automatic verification are confirmed or retested by medical technologists, significantly easing their workload. Analyzed specimens are then moved to a collection box by the unloading system, with their locations recorded for easy retrieval and storage.